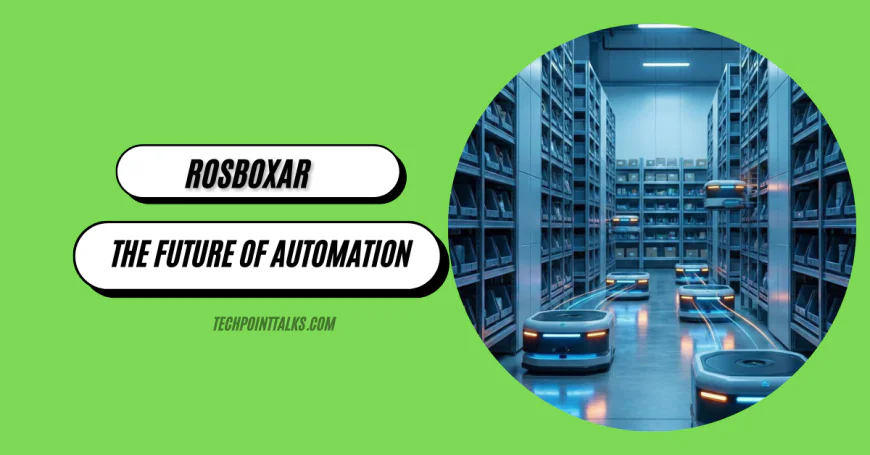

Rosboxar Manufacturing: The Future of Automation

Discover the transformative power of Rosboxar manufacturing technology. We explore its modular architecture, real-world efficiency, and how it is reshaping the future of industrial automation.

In the ever-evolving landscape of industrial production, few innovations have sparked as much conversation on the factory floor as Rosboxar manufacturing technology. Having spent over a decade analyzing assembly line inefficiencies and integrating various automation solutions, I have seen trends come and go, but this shift feels different. We are moving away from the rigid, monolithic machines of the past toward something far more fluid and adaptable. Rosboxar represents a significant leap in modular robotics, essentially creating "smart cells" that can handle complex fabrication tasks without the massive footprint of traditional assembly lines. It is not just about replacing human hands with mechanical ones; it is about creating a symbiotic ecosystem where hardware agility meets advanced software intelligence. For manufacturers dealing with high-mix, low-volume demands, understanding the nuances of this technology is no longer optional—it is becoming a critical survival strategy in a competitive market.

What is Rosboxar Manufacturing Technology?

At its core, Rosboxar manufacturing technology is defined by its enclosed, modular architecture combined with high-precision robotic articulation. Unlike open-gantry systems that require massive safety cages and dedicated floor space, a Rosboxar unit is self-contained and often resembles a large, sophisticated kiosk.

Inside this enclosure is a multi-axis robotic system that automatically switches tools to perform cutting, welding, assembly, or packaging tasks. The "box" aspect is crucial because it controls the environment—temperature, particulate matter, and lighting are strictly regulated to ensure consistency.

From my experience installing these units, the immediate benefit is the reduction in infrastructure changes; you don't need to rebuild your factory to fit the machine. The machine is designed to fit your factory, plugging into existing workflows with a surprising lack of friction compared to legacy automation systems.

The Evolution from CNC to Rosboxar Systems

To truly appreciate where we are today, we have to look back to the era of Computer Numerical Control (CNC) machining. CNC was the gold standard for precision, but it was inherently subtractive and often limited to rigid material handling. Rosboxar technology builds on the precision of CNC while introducing the versatility of additive manufacturing and intelligent assembly.

I remember the frustration of retooling a CNC mill for a new product run—it could take days of downtime and calibration. With Rosboxar systems, the changeover is largely software-driven.

Because the system uses a library of pre-calibrated end-effectors, switching from milling a bracket to assembling a circuit board takes minutes, not shifts. This evolution marks a transition from "hard automation," where machines do one task very fast, to "soft automation," where machines do anything you need them to do at a reasonable speed.

Core Components of a Rosboxar Unit

A standard Rosboxar unit is deceptive in its simplicity from the outside, but the internal engineering is a marvel of modern mechatronics. The primary component is the kinematic drive system, which usually employs a 6-axis or 7-axis arm designed for confined spaces.

This arm is supported by a dynamic vision system—cameras and LiDAR sensors that map the workspace in real time, enabling the machine to compensate for slight misalignments in material placement. During a recent project, I watched a technician accidentally bump a tray of components; a traditional robot would have blindly crashed, but the Rosboxar unit paused, scanned, recalibrated its path, and continued without a single error.

Additionally, the filtration and climate-control systems integrated into the chassis enable these units to operate in "dirty" environments while maintaining cleanroom-level integrity within the work zone, a feature that significantly reduces defect rates in sensitive electronics manufacturing.

Adaptive Grippers and Sensory Feedback

One of the most specific advancements within the Rosboxar ecosystem is the development of adaptive gripping technology. In the past, end-of-arm tooling was dumb; it was either open or closed, with pneumatic pressure doing the heavy lifting. Modern Rosboxar setups utilize force-torque sensors that provide haptic feedback to the central controller.

This means the machine can "feel" if a screw is cross-threaded or if a plastic clip hasn't snapped into place correctly. I have seen these grippers handle fragile glass vials and heavy steel casings in the same cycle without a tool change, simply by adjusting the grip force parameters.

This sensory loop is vital for quality control because it detects errors during the process rather than at the end of the line. It essentially embeds a quality assurance manager within the very arm that builds the product.

The Software Interface and Learning Curves

Hardware is only as good as the code that drives it, and this is where Rosboxar has made the most significant strides toward user-friendliness. Historically, programming an industrial robot required a specialized engineer fluent in proprietary languages like KAREL or RAPID. Today, the Rosboxar interface often uses a visual, block-based programming environment that resembles a flowchart more than a terminal window.

This democratization of programming allows floor managers and technicians to tweak parameters without calling in an expensive external consultant. However, I will be honest—there is still a learning curve. While the basics are intuitive, optimizing cycle times requires a deep understanding of the machine's kinematics.

In my experience, teams that invest in a week of dedicated training for their operators see a faster return on investment than those who treat it as a "plug and play" appliance.

Real-World Applications in Modern Factories

The versatility of Rosboxar technology has enabled it to permeate industries previously resistant to automation due to high variability. A prime example is the custom medical device sector, particularly in prosthetic manufacturing. Each product is unique to the patient, making traditional mass production impossible.

Using Rosboxar units, manufacturers can scan a patient's limb, upload the data, and have the machine carve, assemble, and finish a custom prosthetic with minimal human intervention. I also recently visited a boutique automotive parts supplier that uses these systems to refurbish vintage components.

The machine scans the worn-out part, identifies the wear patterns, and uses laser cladding to restore the metal surface before machining it back to original specifications. These applications demonstrate that automation is no longer just for producing millions of identical widgets; it is now for producing unique items at scale.

Efficiency Gains vs. Implementation Costs

Let's talk about the elephant in the room: the cost. Rosboxar technology is not cheap. The initial capital expenditure for a single fully equipped cell can easily rival the cost of three traditional robotic arms. However, analyzing cost solely by sticker price is a rookie mistake. When you factor in the reduction in floor space, the elimination of safety fencing, and the dramatic drop in changeover downtime, the math starts to look very different.

I worked on a cost-benefit analysis for a mid-sized electronics firm where the ROI for their Rosboxar integration was calculated at 24 months. They achieved it in 14. The efficiency gains come from the machine's ability to run "lights out" shifts—operating overnight without human supervision—effectively doubling production capacity without doubling the payroll.

Solving the "High-Mix, Low-Volume" Dilemma

The "High-Mix, Low-Volume" (HMLV) challenge has always been the Achilles' heel of automation. If you produce 500 units of 50 different products, the setup time usually kills your profit margin. Rosboxar technology is specifically engineered to solve this. Because the environment inside the box is controlled and the tooling is adaptable, switching from Product A to Product B is often just a matter of loading a new software file and swapping a material tray.

I've observed facilities where the production schedule changes hourly, moving from assembling consumer drones to packaging pharmaceutical kits. The Rosboxar units handle this variance with an agility that traditional rigid automation simply cannot match. This flexibility allows smaller manufacturers to bid on contracts that were previously out of reach, leveling the playing field against larger conglomerates.

Maintenance and Durability in Harsh Environments

Durability is a major concern for any plant manager. We need machines that can take a beating and keep running. The enclosed nature of Rosboxar systems gives them a distinct advantage here. By isolating moving parts from the factory environment, wear and tear on gears, belts, and sensors is significantly reduced. I have seen these units operating in foundries where the air is thick with graphite dust—a substance that destroys standard electronics in weeks.

The Rosboxar units, however, remained pristine inside. Maintenance is generally predictive rather than reactive; the system monitors its own motor currents and vibration levels, alerting the maintenance team to lubricate a joint or replace a bearing weeks before a failure occurs. This reliability is crucial for maintaining the "just-in-time" delivery schedules that modern supply chains demand.

Integrating Rosboxar with Existing Assembly Lines

One of the most common misconceptions I encounter is the belief that adopting this technology means scrapping your current line. That is rarely the case. The beauty of Rosboxar lies in its ability to act as an "island of automation" within a traditional workflow. You might keep your manual assembly stations for the intricate, judgment-heavy tasks but insert a Rosboxar unit to handle the repetitive fastening or hazardous gluing stages.

The integration usually involves setting up conveyor handshakes—simple sensors that tell the robot when a part has arrived. In my experience, the biggest challenge isn't the mechanical hookup; it's the data integration. Getting the Rosboxar unit to communicate with a legacy ERP (Enterprise Resource Planning) system can be tricky, but middleware solutions are improving every year to bridge this gap.

Ethical Considerations and Workforce Impact

We cannot discuss automation without addressing the human element. There is a valid fear that technologies like Rosboxar will displace workers. From what I have observed on the ground, the reality is more nuanced. These machines don't usually replace people; they replace tasks—specifically, the dull, dirty, and dangerous ones. The operator who used to spend eight hours tightening screws is now the technician monitoring three Rosboxar units.

This shift requires upskilling, which is an ethical responsibility for any employer. Companies that succeed with this technology invest in their people as much as they invest in their machinery. They create a path for floor workers to become robot programmers and maintenance leads. It transforms the job from manual labor to technical oversight, which is generally less physically taxing and higher paying.

Final Thoughts on Adopting Rosboxar

As we look toward the next decade of manufacturing, the adoption of Rosboxar technology appears inevitable for those who wish to remain agile. The days of setting up a factory to make one thing for ten years are fading. The market demands customization, speed, and quality, all at a competitive price point. Rosboxar offers a viable path to meet these conflicting demands.

It is a mature technology that bridges the gap between the flexibility of a human worker and the consistency of a robot. For manufacturers sitting on the fence, my advice is to start small. Implement a single pilot cell, collect data, and assess workflow changes.

The future belongs to those who can adapt, and Rosboxar is the ultimate tool for adaptation. For more insights into the trajectory of industrial robotics, explore resources from the International Federation of Robotics.

Frequently Asked Questions

1. What is the primary advantage of Rosboxar over traditional robots?

The main advantage is the modular, enclosed architecture that integrates safety, environmental control, and adaptability into a single unit. This eliminates the need for external safety cages and allows for rapid installation and easier reconfiguration for different tasks compared to traditional open-arm robots.

2. Is Rosboxar technology suitable for small businesses?

Yes, it is particularly well-suited for small to mid-sized manufacturers. Its ability to handle high-mix, low-volume production runs efficiently means small businesses can automate diverse product lines without the prohibitive setup costs and downtime associated with traditional mass-production automation.

3. How long does it take to program a new task on a Rosboxar unit?

With modern block-based programming interfaces, a simple task can be programmed in a few hours. More complex operations requiring precise force feedback or vision system integration might take a few days, but this is still significantly faster than legacy coding methods.

4. Can Rosboxar units operate in dirty or hazardous environments?

Absolutely. The "box" design specifically protects the internal robotics and sensitive electronics from external contaminants like dust, oil mist, and heat. This makes them ideal for foundries, welding shops, or chemical processing plants where open robots would fail.

5. What is the typical return on investment (ROI) time frame?

While initial costs are high, the typical ROI is between 12 to 24 months. This rapid return is driven by reduced changeover times, lower scrap rates, the ability to run unmanned overnight shifts, and the minimal infrastructure modifications required for installation.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0