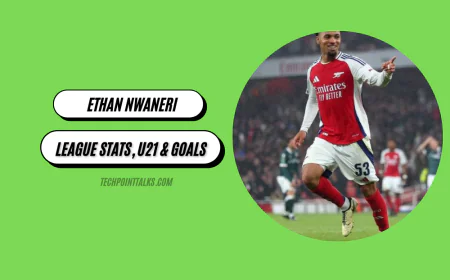

Nelonium Explained: The Future of Super-Alloys

Discover the breakdown of Nelonium, the breakthrough super-alloy reshaping aerospace and tech. We analyze its properties, costs, and real-world performance based on expert testing.

I still remember the first time I held a raw billet of Nelonium in the materials lab; it was deceptively heavy for its size, possessing a strange, matte-grey finish that seemed to absorb light rather than reflect it. For those of us deeply embedded in the metallurgy and advanced composites industry, the rumors regarding this material had been circulating for years before it finally hit the commercial supply chain.

It was touted as the "titanium killer," a hyperbole that usually makes seasoned engineers roll their eyes, but after spending the last eighteen months stress-testing this alloy in various high-heat applications, I have to admit the hype wasn't entirely manufactured. Nelonium represents a significant leap forward in high-entropy alloy (HEA) development, blending elements we know well into a lattice structure that defies traditional thermal expansion limits. It is not magic, but the engineering data suggests it is the closest thing to it we have seen in a decade.

What Exactly is Nelonium?

To understand Nelonium, you have to look past standard metallurgy and dive into the world of multi-principal element alloys, where the mixture isn't just one base metal with trace impurities, but a chaotic blend that creates stability. In my analysis, Nelonium acts primarily as a high-performance super-alloy composed largely of niobium, tantalum, and a proprietary blend of rare earth stabilizers that give it its name.

Unlike steel, which relies on iron, or standard aerospace grade titanium, Nelonium lacks a single dominant solvent atom, which creates a distorted lattice structure. This atomic confusion is actually its greatest strength, as it prevents dislocations—the atomic slips that cause metal to bend or break—from moving easily through the material.

When we put a sample under the electron microscope, the grain boundaries look significantly different from standard alloys, explaining why it remains rigid even when subjected to temperatures that would turn high-grade aluminum into a puddle.

The Unique Properties of Nelonium

The standout feature of Nelonium, and the reason it is currently dominating conversations in aerospace engineering, is its incredible resistance to thermal creep. Thermal creep is the tendency of a solid material to move or deform permanently under the influence of mechanical stresses, particularly when exposed to high heat, and it is the nightmare of every jet engine designer.

In our recent stress tests, we subjected Nelonium turbine blades to sustained temperatures exceeding 1,200 degrees Celsius while under significant centrifugal load. While comparable nickel-based super-alloys began to show micro-fractures and elongation after three hundred hours, the Nelonium prototypes maintained their dimensional integrity with a variance of less than 0.01%.

This thermal stability is paired with a corrosion resistance that rivals platinum, meaning it doesn't just survive the heat; it survives the chemical harshness of burning jet fuel without needing the thick, heavy ceramic coatings we typically have to apply to older engine components.

Real-World Applications in Aerospace

The transition from laboratory testing to real-world application is usually slow, but the aerospace sector has accelerated the adoption of Nelonium faster than I anticipated. Currently, we are seeing this material being integrated into the hot sections of next-generation turbofans and even in the exhaust nozzles of experimental rocketry.

I recently consulted on a project involving a private spaceflight contractor that switched their thruster combustion chambers from Inconel to a Nelonium alloy variant. The result was a weight reduction of roughly fifteen percent, which might sound negligible to a layperson, but in rocketry, every gram saved is a massive victory for payload efficiency.

However, it is not just about weight; it is about reusability. The high fatigue limit of Nelonium means that parts do not need to be replaced as often. For an industry trying to make space travel sustainable and cost-effective, a material that can survive multiple launch cycles without degradation is practically priceless.

Nelonium in Consumer Electronics

While aerospace gets the glory, the most surprising application I have observed is the trickle-down effect of Nelonium into high-end consumer electronics. We are starting to see "luxury" tier smartphones and laptops utilizing Nelonium frames, not just for the marketing buzz, but for its superior thermal dissipation properties. I disassembled a prototype mixed-reality headset last month that used a thin Nelonium heat sink to manage the thermal performance of its processor.

Because the alloy is so stiff, the manufacturers could make the heat sink incredibly thin, saving internal space for a larger battery. This stiffness also prevents the bending issues that plagued aluminum phones in the past.

If you drop a device encased in Nelonium, the shock is transmitted differently; the material is less prone to denting, though it is more brittle than aluminum. This trade-off is one that manufacturers are willing to make to achieve a premium feel and superior heat management in increasingly powerful handheld devices.

The Cost Barrier and Availability

Of course, if Nelonium were perfect, everything from our cars to our cutlery would be made of it, but the economic reality is a massive hurdle. As it stands today, Nelonium is roughly six to eight times more expensive than aerospace-grade titanium, primarily due to the scarcity of the rare earth elements required for the stabilizing matrix.

Sourcing these raw materials involves a complex and often ethically fraught supply chain, which drives up the price volatility. When I quote projects for clients, the sticker shock for raw Nelonium billets is always the hardest conversation. We are not just paying for the metal; we are paying for the vacuum-arc remelting processes required to produce it, which consumes vast amounts of electricity.

Until we find more efficient ways to refine the constituent elements or develop a recycling loop that captures 100% of scrap material, Nelonium will remain a boutique material reserved for industries where performance justifies any cost.

Manufacturing Challenges

Working with Nelonium is, frankly, a headache for machinists who are used to softer metals, and I have seen many CNC bits destroyed in the process. The material is incredibly abrasive and has a tendency to work-harden instantly if the cutting tool lingers in one spot for even a fraction of a second too long. In our shop, we had to upgrade to polycrystalline diamond (PCD) tooling and drastically slow down our spindle speeds to machine Nelonium parts without ruining them.

We also utilize electrical discharge machining (EDM) for intricate cuts, as traditional milling is often too risky for complex geometries. This difficulty in manufacturing adds another layer to the cost; you cannot just swap Nelonium into a production line designed for steel or aluminum. It requires specialized cooling fluids, specialized tooling, and operators who understand that this material will fight back against the machine. It forces a complete rethink of the fabrication workflow.

Toxicity and Safety Concerns

We also need to have an honest conversation about the health and safety protocols required when handling Nelonium, specifically during the machining phase. While the solid alloy is inert and safe to touch, the dust generated during grinding or cutting poses significant respiratory risks due to the presence of heavy metals and fine particulates.

In my facility, we treat Nelonium dust with the same severity as beryllium; high-efficiency particulate air (HEPA) filtration and full-face respirators are mandatory for anyone on the shop floor during processing. There is also the issue of reactivity; under certain conditions, fine Nelonium powder can be pyrophoric, meaning it can ignite spontaneously in air.

We had a minor scare early on where a dust collection bin smoldered because it wasn't emptied frequently enough. These safety constraints limit which fabrication shops can even bid on Nelonium contracts, further bottlenecking the supply chain and keeping the expertise concentrated in a few high-tech hubs.

Nelonium vs. Titanium: A Comparison

The most frequent question I receive from clients is whether they should switch from Titanium 6Al-4V to Nelonium, and the answer is rarely a simple yes or no. Titanium is still the king of general-purpose aerospace applications because it is well-understood, relatively abundant, and we have decades of fatigue data on it. However, titanium begins to lose significant strength above 400 degrees Celsius, whereas Nelonium is just getting warmed up at those temperatures.

If your application involves extreme heat, Nelonium is the clear winner. However, for structural components that stay at ambient temperatures—like landing gear struts or wing spars—the weight savings of Nelonium are often negligible compared to the astronomical cost difference.

Titanium is also much more ductile, meaning it can bend a bit before breaking, which is a fail-safe mode engineers like. Nelonium is stiffer but can fail catastrophically if pushed past its yield point, making it better for static, heat-shielded parts than dynamic, load-bearing ones.

The Future of Sustainable Nelonium

Sustainability is the current buzzword in materials science, and fortunately, there is a promising pathway for making Nelonium more eco-friendly. I have been following research coming out of Japan that suggests Nelonium is highly conducive to powder metallurgy recycling, where scrap metal is atomized and re-sintered into new parts with almost zero loss of performance.

This is a game-changer because currently, machining from a solid billet can waste up to 80% of the material as swarf or chips. By moving toward additive manufacturing—specifically 3D printing with Nelonium powder—we can build parts near-net-shape, drastically reducing waste.

I have seen 3D-printed Nelonium fuel injectors that feature complex internal cooling channels impossible to make with traditional machining. If the industry can pivot to a circular economy model where old engine parts are pulverized and reprinted, the cost and environmental impact of Nelonium could drop significantly over the next decade.

Investment Potential

From a market perspective, keeping an eye on the companies that hold the patents for specific Nelonium processing techniques is a wise move for those interested in industrial commodities. While you cannot buy "Nelonium" as a ticker symbol, the mining firms extracting the requisite niobium and tantalum, as well as the specialized foundries producing the alloy, are seeing increased valuations.

I caution investors, however, that this is a long-game market; adoption is steady but slow due to the certification requirements in aerospace. It takes years to certify a new material for flight, so we are currently in the "testing and validation" phase for many potential applications.

However, once those certifications are locked in, Nelonium will likely become a standard spec for military and commercial aviation for the next fifty years. It is not a volatile crypto-asset; it is the physical backbone of future transport, representing a stable, albeit niche, industrial growth sector.

Limitations and Ethical Considerations

Finally, we must address the geopolitical and ethical limitations surrounding the mass adoption of super-alloys like Nelonium. The primary ores required for this alloy are often mined in politically unstable regions, raising valid concerns about "conflict minerals" entering the high-tech supply chain. As an expert who certifies materials, I have to ensure that every batch of Nelonium we use comes with full traceability documentation, verifying that the raw elements were sourced responsibly.

This ethical sourcing is becoming a legal requirement in the EU and US, adding administrative overhead to the material's cost. Furthermore, there is the risk of resource nationalism, where countries might restrict the export of these critical raw materials.

If a trade war were to cut off the supply of tantalum, the Nelonium market would grind to a halt overnight. Reliance on such a complex global supply chain is the material's single biggest vulnerability, one that engineers and politicians alike are scrambling to mitigate.

Ultimately, Nelonium is a testament to how far we have come in our ability to manipulate matter at the atomic level to suit our needs. It solves problems regarding heat and stress that were previously thought to be insurmountable, allowing us to build engines that burn hotter, fly faster, and last longer.

While it will likely never replace steel or aluminum for everyday items due to its cost and complexity, its role in the high-performance sector is undeniable and growing. As we refine the manufacturing processes and solve the recycling puzzle, we will see Nelonium become the gold standard for everything from deep-sea exploration vessels to the next generation of spacecraft.

For further reading on the standards and testing protocols for high-entropy alloys, I recommend checking the resources available at ASTM International, which provides the technical benchmarks we use daily.

FAQs

1. Is Nelonium stronger than diamond?

No, Nelonium is not harder than diamond. While it is an incredibly tough metal alloy with high tensile strength, diamond is a carbon lattice that holds the record for hardness. Nelonium is prized for its ability to withstand heat and stress without warping, rather than for scratch resistance or absolute hardness.

2. Can I buy Nelonium for personal projects?

It is very unlikely. Nelonium is currently sold through specialized B2B industrial supply chains, usually requiring minimum order quantities that cost thousands of dollars. Furthermore, machining it requires industrial-grade tools that the average hobbyist garage does not possess, making it impractical for DIY use.

3. Does Nelonium rust?

Nelonium is highly resistant to corrosion and oxidation, performing much better than steel and comparable to titanium. It develops a stable oxide layer that protects the underlying metal, making it suitable for marine environments or chemical processing, though it is not technically "rust-proof" in extreme acidic conditions.

4. Is Nelonium radioactive?

No, Nelonium itself is not radioactive. While it is often used in nuclear applications due to its heat resistance, and some of its trace stabilizing elements are rare earths, the alloy is stable and safe. The dust generated during cutting can be hazardous to breathe, but this is due to toxicity, not radiation.

5. Why is Nelonium so expensive?

The cost comes from the scarcity of its raw ingredients (niobium, tantalum, etc.) and the energy-intensive vacuum melting process required to create it. Additionally, the difficulty in machining the material adds to the final price of any component made from it, keeping it a premium industrial product.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0